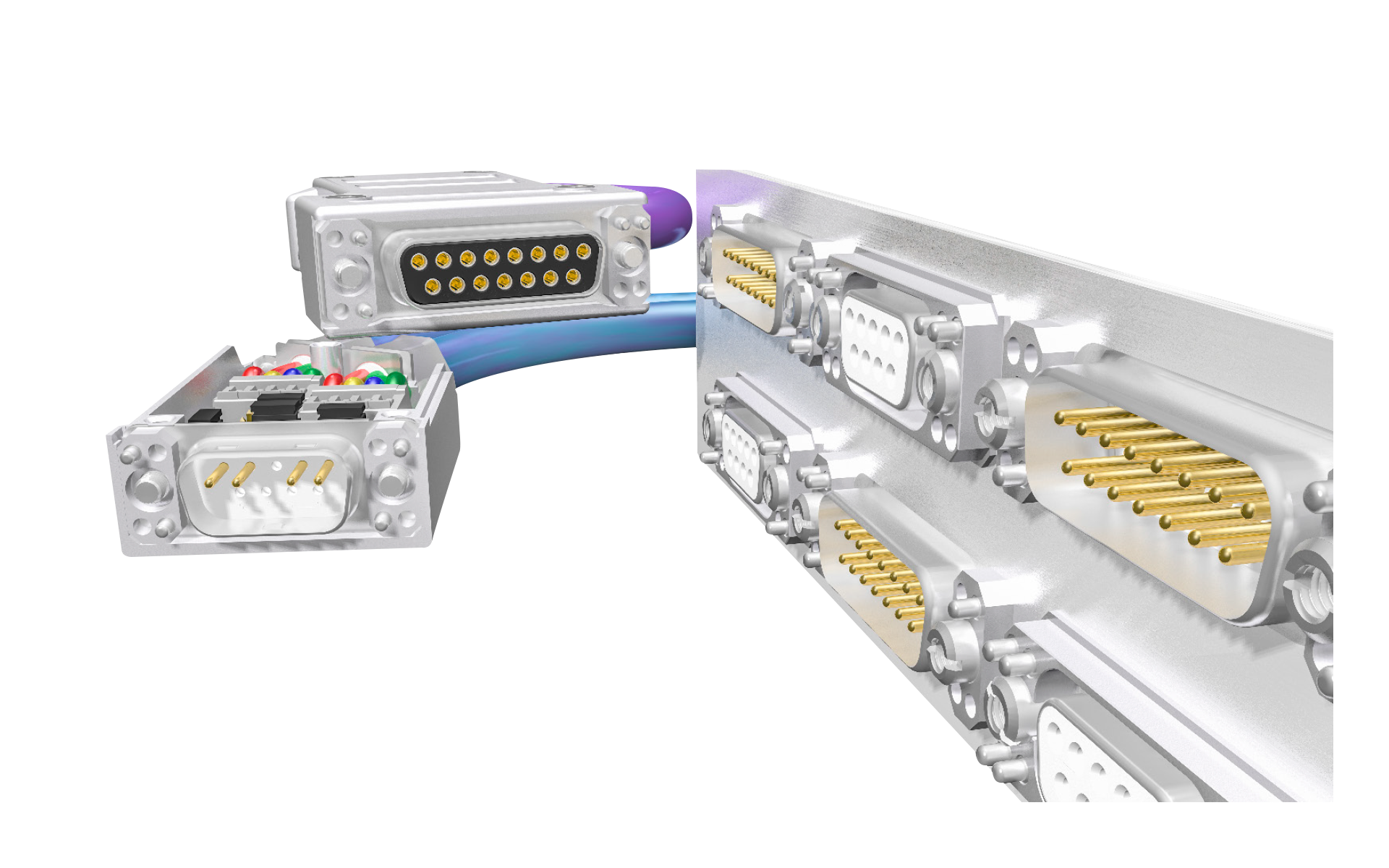

Coding system for D-Sub interfaces

The solution to avoid wrong connections – secure, reliable and flexible

Highly sensitive measurement, control and communication devices require an efficient protection against accidental abusive mismatching. Visual instructions and colored labeling are not sufficient. Just a minimal contact, only for the fraction of a second, may cause a voltage flashover and damage the terminal device. Not only the risk of repair cost caused by such kind of incident but also the potential consequences like a system breakdown or e. g. an inoperative train may underline the importance of a mechanical coding of critical interconnections as an indispensable safety factor.

Having specialized in EMC interconnection solutions, Inotec electronics GmbH has developed a unique D-Sub coding system for hoods with screw locking. It does not only reliably avoid mismatching, it also improves the EMI / RFI shielding performance of the interface by providing a consistent full metal contact.

Having specialized in EMC interconnection solutions, Inotec electronics GmbH has developed a unique D-Sub coding system for hoods with screw locking. It does not only reliably avoid mismatching, it also improves the EMI / RFI shielding performance of the interface by providing a consistent full metal contact.

Coding system for D-Sub interfaces

- Up to 70 coding versions offers protection against unintentional or abusive mating of connectors

- Full metal coding elements improve grounding contact for optimal EMC

- Coding elements are either riveted to the connector shell or screwed on the device

- Accurate alignment with special positioning device

- Easy insertion of the coding pins with special pre-adjusted hand tool

- Suitable for all Inotec D-Sub hoods prepared for coding (see symbol)

- Can be variably used with M3 or 4-40 UNC jackscrews

- Easy to process in workshop or field

Secure

- Up to 70 coding versions offer protection against unintentional or abusive mating of connectors

- Full metal coding elements improve grounding contact for optimal EMC

Robust

- Coding elements are either riveted to the connector shell or screwed on the device

- High-end and precise full metal components

Reliable

- Accurate alignment with special positioning device

- Inserting the coding pins process-reliable thanks to a preset tool

Flexible

- Suitable for all codable Inotec D-Sub hoods

- Easy to process in workshop or field assembly

- Can be variably used with M3 or 4-40 UNC jackscrews